In this project, we propose the use of digital twins to inspect advanced manufacturing parts. By using virtual reality, we can achieve a process that can be both quicker and provide a more complete understanding of possible printing defects and how they relate to each other and the overall part.

Existing techniques have proposed multiple ways to perform multiscale navigation in VR, either in continuous or discrete ways. These techniques, however, (1) focus mostly on structures with well-defined hierarchical meaning (such as the human body) or (2) happen in open areas (such as a map on a game), not accounting for the nuances of inspecting a solid, homogeneous object.

From the domain perspective, (3) while such parts can be objects with significant size, most of the defects happen at a millimeter to centimeter scale, making it hard to navigate through the object that is one or more orders of magnitude larger; and (4) since these defects take place at specific truces that are the structural part building the object, they are often occluded inside the object, making it hard to visually inspect them from the outside.

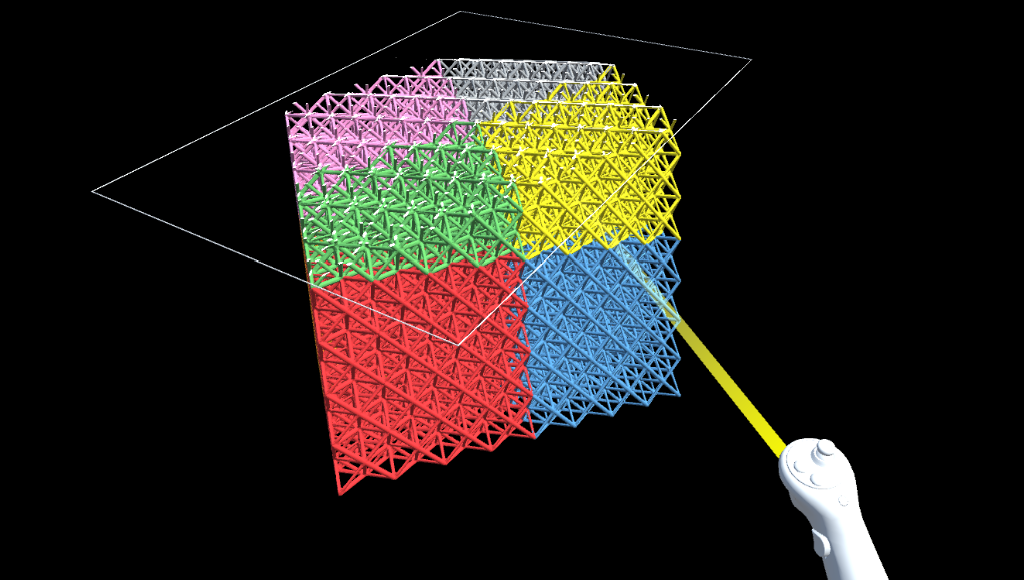

We propose the Progressive Refinement for the Inspection of Multiscale Objects (PRIMO) technique as a solution to those challenges. It progressively subdivides an object into octets, allowing users to focus on a subset region of the object. Compared to existing techniques, PRIMO provides a more structured and systematic way of navigating through large objects, achieving small levels of scale that allow the visualization of details of the object.

Proceedings Articles

Exploring Multiscale Navigation of Homogeneous and Dense Objects with Progressive Refinement in Virtual Reality Proceedings Article

In: 2025 IEEE Conference Virtual Reality and 3D User Interfaces (VR), pp. 228-237, 2025.